Anaerobic Digestion

ASUR™

Anaerobic Sequential Up-flow Reactor

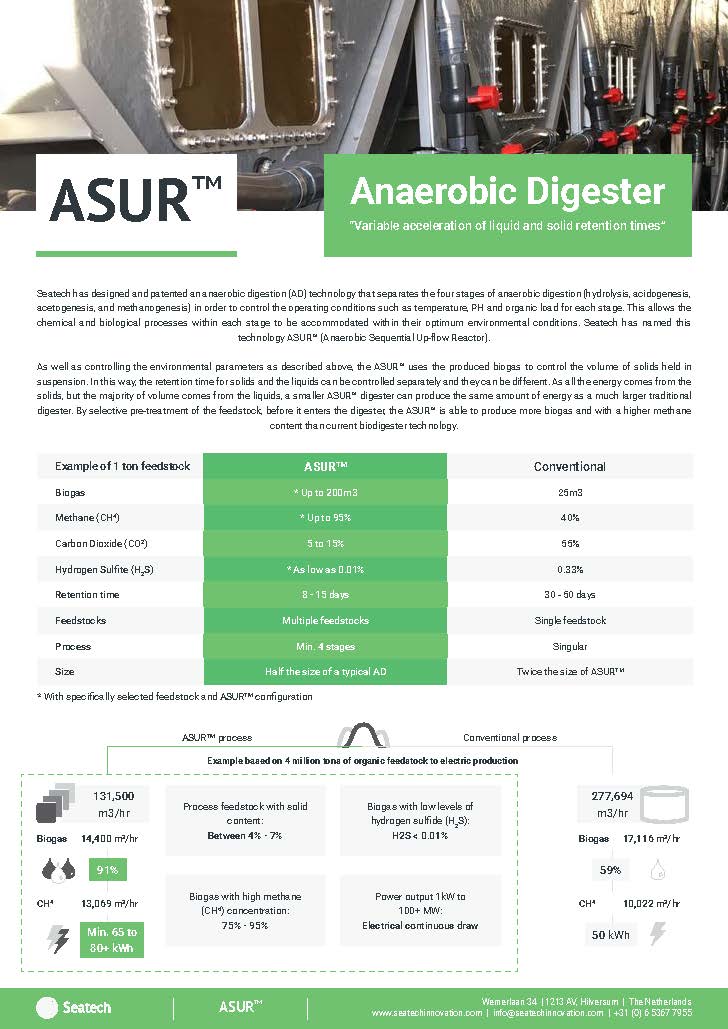

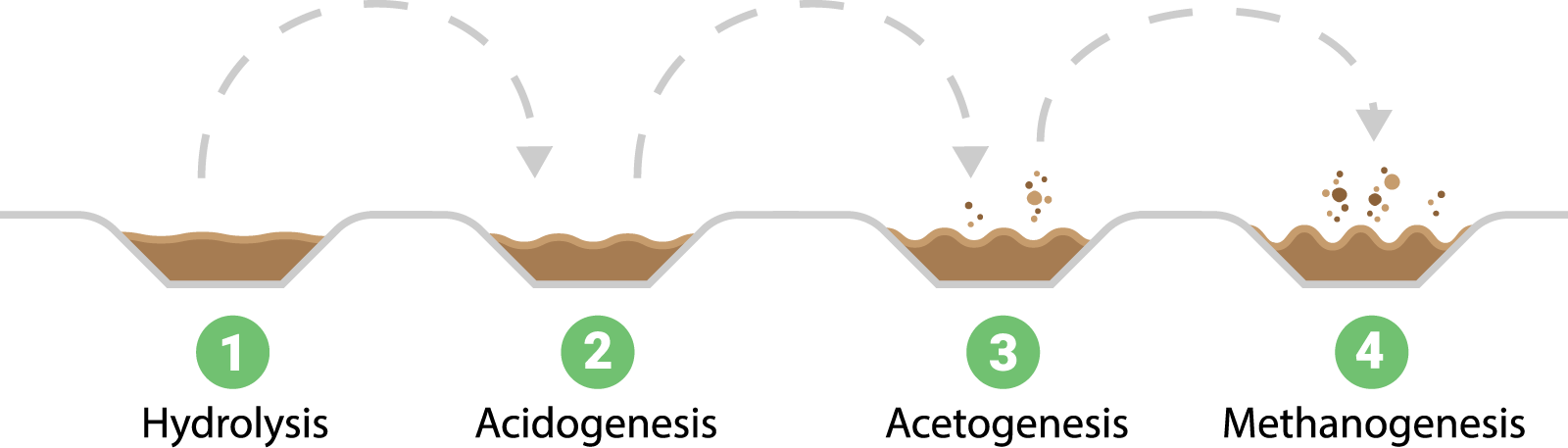

Seatech has designed and patented an anaerobic digestion (AD) technology that separates the four stages of anaerobic digestion (hydrolysis, acidogenesis, acetogenesis, and methanogenesis) in order to control the operating conditions such as temperature, PH and organic load for each stage. This allows the chemical and biological processes within each stage to be accommodated within their optimum environmental conditions. Seatech has named this technology ASUR™ (Anaerobic Sequential Up-flow Reactor). As well as controlling the environmental parameters as described above, the ASUR™ uses the produced biogas to control the volume of solids held in suspension. In this way, the retention time for solids and the liquids can be controlled separately and they can be different. As all the energy comes from the solids, but the majority of volume comes from the liquids, a smaller ASUR™ digester can produce the same amount of energy as a much larger traditional digester. By selective pre-treatment of the feedstock, before it enters the digester, the ASUR™ is able to produce more biogas and with a higher methane content than current biodigester technology.

The effluent from the digester is high in nitrates, phosphates and potassium, as well as possessing a high level of fresh water. This provides a high-grade fertilizer which can be used directly on the crops and the water for irrigation, limiting the need for desalination.

Benefits of ASUR™

Seatech has designed and patented an anaerobic digestion (AD) technology that separates the four stages of anaerobic digestion (hydrolysis, acidogenesis, acetogenesis, and methanogenesis) in order to control the operating conditions such as temperature, PH and organic load for each stage. This allows the chemical and biological processes within each stage to be accommodated within their optimum environmental conditions. Seatech has named thistechnology ASURTM (Anaerobic Sequential Up-flow Reactor).

As well as controlling the environmental parameters as described above, the ASURTM uses the produced biogas to control the volume of solids held in suspension. In this way, the retention time for solids and the liquids can be controlled separately and they can be different.

Datasheet

| Example of 1 ton feedstock | ASUR™ | Conventional |

|---|---|---|

| Biogas | * Up to 200m3 | 25m3 |

| Methane (CH4) | * Up to 95% | 40% |

| Carbon Dioxide (CO2) | 5 to 15% | 55% |

| Hydrogen Sulfide (H2S) | * As low as 0.01% | 0.33% |

| Retention time | 8 – 15 Days | 30 – 50 days |

| Feedstocks | Multiple feedstocks | Single feedstock |

| Process | Min. 4 stages | Singular |

| Size | Half the size of a typical AD | Twice the size of ASUR™ |

* With specifically selected feedstock and ASUR™ configuration

By using local anaerobic digesters, the size of landfills can be severely reduced by disposing of waste and converting it into a biogas.

Applications

Introduction to topic here. Introduction to topic here. Introduction to topic here. Introduction to topic here. Introduction to topic here.

Energy production

By processing seaweed and organic waste through our ASUR™ digestion process, Seatech can produce a biogas with a very high methane content.

Waste reduction

The ASUR™ can process large amounts of organic-waste, resulting in a reduction of landfills and the conversion of organic waste to usable products.

Fertilizer

The ASUR™ digestion sequence can produce a high grade fertilizer which can also be used for desert greening.

Applications

Introduction to topic here. Introduction to topic here. Introduction to topic here. Introduction to topic here. Introduction to topic here.

Energy production

By processing seaweed and organic waste through our ASUR™ digestion process, Seatech can produce a biogas with a very high methane content.

Waste reduction

The ASUR™ can process large amounts of organic-waste, resulting in a reduction of landfills and the conversion of organic waste to usable products.

Fertilizer

The ASUR™ digestion sequence can produce a high grade fertilizer which can also be used for desert greening.